Anyone who’s ever opened a new iPhone—or any Apple product, really—understands the impact of well-designed packaging. Their boxes are clean and sleek. Each piece nested, boxed, and wrapped to perfection with no wasted space or clutter. A slick little tab here and there to help you extract items that are flush to edges of the box.

Anyone who’s ever opened a new iPhone—or any Apple product, really—understands the impact of well-designed packaging. Their boxes are clean and sleek. Each piece nested, boxed, and wrapped to perfection with no wasted space or clutter. A slick little tab here and there to help you extract items that are flush to edges of the box.

Before you even touch the phone itself, you get your first taste of the technology’s expert craftsmanship and clean, user-friendly design. You learn a few things about the company, too. They care about every aspect of your experience as a customer. And they must have a lot of pride for the product inside that perfectly engineered box.

Imagine if you could deliver steel that way.

Each trailer perfectly balanced, loads sequenced and arranged to your erector’s preferences, pieces and bundles packaged and nested with your customer’s offloading capabilities in mind. Imagine what your partners in the field could learn about your company before they set a single piece of steel into place.

Around the world, a number of forward-thinking steel fabricators, such as CoBuilt, LLC., in Memphis, Tenn., are already beyond imagining. They’re making it happen and separating themselves from the competition with the help of SDS2 Load Planning.

“Everyone thinks the job is done once it shows up for shipping,” said Bryan Boggs, Director of Production at CoBuilt. “But it’s still got to be loaded out correctly and efficiently and in the format they want. [SDS2 Load Planning] has been a game-changer for us.”

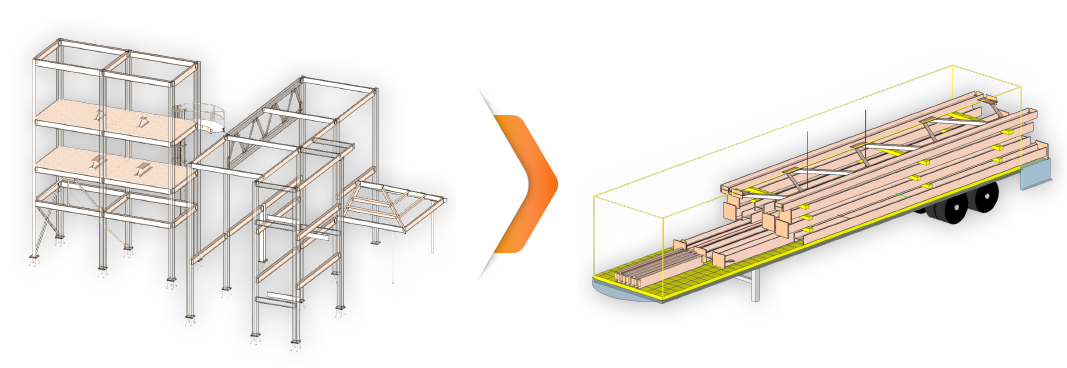

This disruptive software allows you to transform any IFC 2x3 file from your preferred modeling software into a balanced and optimized 3D loading plan.

In addition to helping shops reduce material handling, increase safety, and optimize shipments, SDS2 Load Planning is also giving many companies a competitive advantage with user-focused delivery and a first impression that lasts.

You're not just selling steel—you're selling an experience.

Let’s talk about Apple again for a moment. One hallmark of their success is their focus on selling not just products, but experiences. Users remember what it feels like to open that smooth white box, and they look forward to doing it again. And whether you love Apple or hate them, there’s no question—and it’s no accident—that they have some of the most loyal customers in the tech world.

Loyalty and relationships go a long way in the steel trade, too. And you may be thinking, sure, but there’s a big difference between a handheld mobile device and a 46-foot long, 22,000-pound steel column. You’re right, of course. Size is precisely the difference, and it makes the experience you sell that much more important to your partnerships and customer relationships.

Think of the experience you could provide your partners in the field if you could envision, engineer, and execute a strategic loading plan. SDS2 Load Planning is giving companies like CoBuilt the power to:

- Fabricate and deliver steel in the order the erector will need it.

- Arrange members and bundles so that piecemarks will be visible, rather than expecting the erectors to sift through pieces to find what they need.

- Place dunnage and set up loads according to the capabilities and capacity of forklifts, cranes, and other unloading equipment.

- Provide detailed 2D and 3D load maps so erectors know exactly where to find the pieces they need.

All these little details—which are not little at all when it comes to steel—are dramatically accelerating fieldwork timelines, increasing safety, and setting projects up for success.

SDS2 Load Planning allows you to take any IFC 2x3 file and turn it into a perfectly balanced load plan.

Project files courtesy of AmFab Steel.

Take pride in your work, and customers will take notice.

As a company, CoBuilt emphasizes continuous improvement and has built a culture where every team member—from upper management and detailers to the welders, fitters, and loaders—take pride and ownership in their work.

Since adopting SDS2 Load Planning, they’re realizing how critically loading and shipping play into that, especially in recent years as they have shifted from commercial clients to retail and shipping giants like Amazon, DHL, and UPS, who have high demands on quality and delivery.

“These guys want bolt-up, they want it to look pristine, and they’re paying for it,” Boggs said. “[SDS2 Load Planning] is giving us one more tool to provide the level of service that they ask for. And it lets us continue to be, as we want to be, their steel fabricator of choice.”

“SDS2 Load Planning is giving us one more tool to provide the level of service that they ask for. And it lets us continue to be, as we want to be, their steel fabricator of choice.”

- Bryan Boggs, CoBuilt, LLC

Because the last work they do on the production floor is the first thing the customer sees, Boggs said, the quality of the loadout is just as critical as the fabrication itself. And because they’re maintaining a live load schedule, shipping upwards of 1,000 tons a month all across the country, they don’t have time for the typical trial-and-error loading processes most fabricators rely upon.

Being intentional with their loading process and involving their loaders in a plan to be more efficient, safe, and organized, helps those loaders see the value and importance of their work. “They’re really buying into it and taking ownership,” Boggs said.

And they’re gaining expertise in the process. Like many companies, CoBuilt has a shipping expert who would previously “play Tetris in his head,” to coordinate their loadouts. SDS2 Load Planning is giving him an opportunity to mentor others and begin to share his decades’ worth of experience, which will help CoBuilt maintain a reliable and long-term commitment to quality.

“We’re getting better,” Boggs said—on shipping time, packaging, and quality. “And our customers are noticing that. That all flows into how we want to be creating separation for us, so people see a noticeable difference between CoBuilt steel and someone else’s.”