SDS2 customers detail renovation of historic Times Square building, home of the famous New Year’s Eve Ball Drop

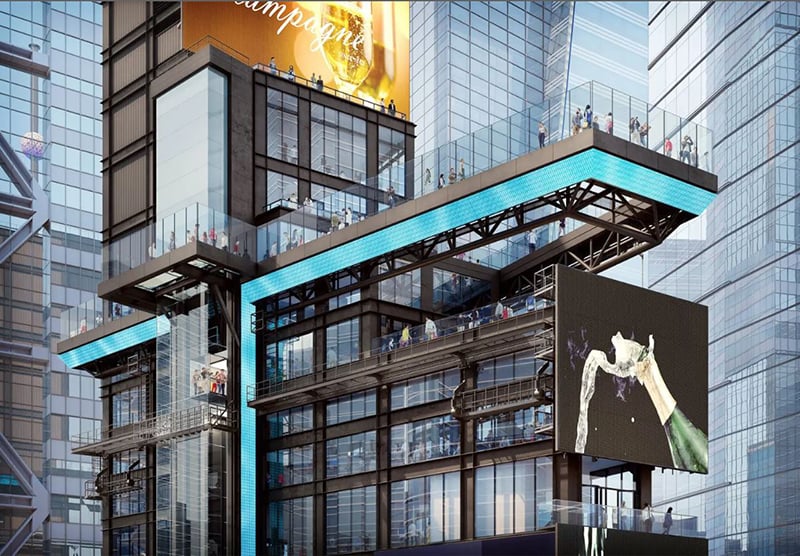

Since 1906, One Times Square has been the epicenter of New Year’s Eve celebrations in the United States as the home of the New Year’s Eve ball drop. Today, the iconic building is undergoing a major renovation, transforming One Times Square into a year-round tourist attraction. Topped by a new viewing deck, the building will give visitors a view of Times Square from 19 stories up—as well as a closer look at the New Year’s Eve ball, which spans 12 feet in diameter and weighs nearly 12,000 pounds.

The renovation will also breathe new life into the building’s interior, which has housed little of interest since its original tenants, The New York Times, left in 1913. Since the 1990s, the building has largely functioned as a digital billboard display. While the billboards will remain, the renovation will transform 18 stories inside into an interactive exhibition that’s part museum and part digital experience with virtual- and augmented-reality displays from various brands.

At the backbone of this $500-million project are SDS2 customers Kennebec Valley Detailers and their trusted fabrication partners, Orange County Ironworks, who have been working for over four years now to fashion new steel to the historic steel frame—all while keeping the building’s million-dollar billboards and six-ton crystal ball intact and operational.

The project earned Kennebec second place in the 2023 SDS2 Solid Steel Awards in the Commercial, Small Tonnage category. Below, we’ll take a closer look at how they brought the project to life, overcoming challenges in detailing, fabrication, and logistics.

Architectural render of One Times Square renovation viewing deck. Photo provided by Kennebec Valley Detailers.

Architectural render of One Times Square renovation viewing deck. Photo provided by Kennebec Valley Detailers.

A Marathon Project

Kennebec was awarded the One Times Square project in July 2020, chosen by Orange County because of their long history of tackling major projects together in New York City and across the region.

The Kennebec team, which is now largely cloud-based and spread across several states, boasts a collective total of over 250 years of SDS2 detailing experience.

“When going into extremely difficult projects it’s imperative you partner up with a team you have confidence in,” said Matt Messing, Senior Vice President of Operations at Orange County. “These jobs are a marathon, so you have to pick your partners very carefully.”

They have been working on the project now for almost four years. “Due to various components required to reinforce the existing structure and retain access to the building, it was done bits at a time,” said James O’Connor, Kennebec’s systems manager.

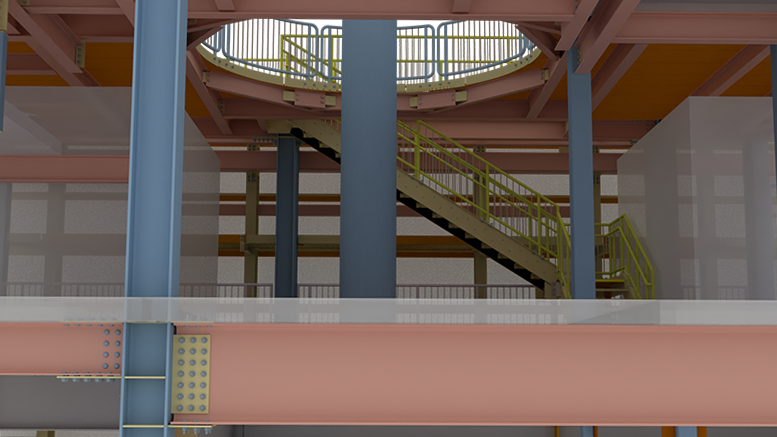

Inside the renovation at One Times Square. Photo provided by Kennebec Valley Detailers.

Inside the renovation at One Times Square. Photo provided by Kennebec Valley Detailers.

Modeling Historic Steel

O’Connor estimated that around 80 percent of the building’s original steel remained and had to be worked around throughout the renovation, which presented a number of challenges.

For one thing, many of the wide flange shapes used in 1903, when the building was constructed, are no longer included in AISC manuals. They also encountered other oddities, such as beams sitting on top of columns, new columns that had to be attached to existing columns, and more. While they found the reference drawings—from both the original construction and another renovation in 1964—to be fairly accurate, they still had to manage the existing steel, which was imported into SDS2 as an IFC model, throughout the project.

“Some things came in okay, others did not,” O’Connor said. “We were provided a model for columns that required a fair amount of reinforcement that in the end we found out was inaccurate and needed to be fixed to meet the proper field condition.”

“Any issue at input had a ripple effect,” he said. “Through surveys, we had to fix things heavily along the way, which led to existing members being input by hand as well.”

In With the New

In addition to working around the existing structure, One Times Square also presented some interesting design and field challenges for the Kennebec and Orange County teams. Wherever possible, the detailers utilized automated tools in SDS2 to save time—such as auto detailing, using the Shuriken (Atlas Tube) component to add HSS splices, and applying basic connections and welds in the model with SDS2’s automated connection design.

“Once set up for typical beams we were able to do simple connections pretty easily,” O’Connor said. “This saves a ton of time once you get a system going. Auto detailing and the ability to put welds in the model also saved a lot of time without having to look at the calculation sketches so much.”

This allowed them to focus their energy on more complex problems—of which there were plenty.

The wedge-shaped building created difficult angles throughout the structure.

On the lower floors, getting beams and columns into place was complicated by the lack of crane access. Beams had to be short enough—less than 16 feet—to fit in the building’s service elevator, and then bolted together to meet the required span length.

“There were a lot of end plate splices,” O’Connor said. “The check bolt function in SDS2 was very helpful in working through tight connections.”

The upper floors had many different elevations to work with, along with a lot of miscellaneous steel, including grating and railing around the famous ball.

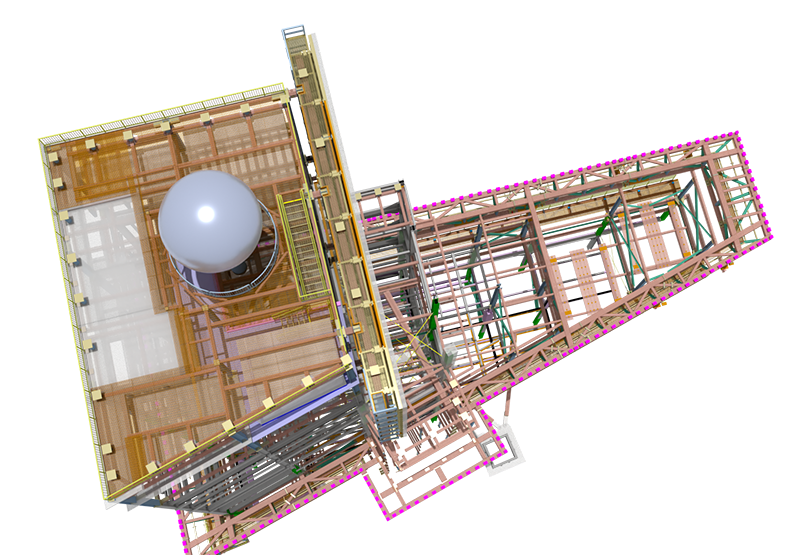

Below the New Year’s Eve ball. Model provided by Kennebec Valley Detailers. Rendered in Blender by SDS2.

Below the New Year’s Eve ball. Model provided by Kennebec Valley Detailers. Rendered in Blender by SDS2.

The viewing deck, which supports a glass floor, was designed with round HSS trusses in the form of a triangle. The trusses were detailed as grouped members, so the Kennebec team had to get creative when any changes came through, sometimes working to save details as standards and copying dimensions to re-detailed members.

“To be honest, we wouldn’t have been able to truly figure out levels 19 and up without using 3D / SDS2,” said Orange County’s Messing. “Not only from a fabrication standpoint, but from a logistics standpoint as well. We had hours of meetings with Kennebec Valley and our engineers just trying to figure things out in the model.”

Top view of One Times Square New Year’s Eve Ball and viewing deck. Steel model provided by Kennebec Valley Detailers. Rendered in Blender by SDS2.

“At the end of the day, it’s about relationships and service,” Messing said. “There are thousands of detailers all over the world that can now be tapped for services but if you are not on the same page, it makes things so much more complicated, and the results always trickle down to the shop and ultimately the field.”

The final pieces of steel were placed this December, with a topping off ceremony held on Thursday, December 7—just in time for the cranes to be removed before the holidays and famous new year celebration.

Kennebec Valley Detailers was founded in 2006 by Larry Hunter in Augusta, Maine. They have since become a cloud-based detailing company, with 15 experienced employees across several states. They work on several types of buildings ranging from small commercial buildings to new and retrofit high-rise buildings throughout New York City and across the northeast.

Orange County Ironworks, LLC, in Montgomery, NY, specializes in the fabrication and delivery of structural steel and miscellaneous iron while serving the New York City and Tri-State areas for over a decade. Their portfolio includes many notable New York locations, including One World Trade, Madison Square Garden Park Tower, 75 Rockefeller Plaza, and more.