Consistently and quickly generating accurate bids for structural steel projects is a formidable challenge at the best of times. The uncertainty that has plagued the markets in recent years, with supply chain woes and unheard-of lead times, makes it even harder—and more critical to business growth.

Unfortunately, the traditional estimating process, which relies on highlighters, spreadsheets, and redundant data entry, is both time consuming and vulnerable to error and inconsistency. That’s why many fabricators are turning to a new method that helps them not only increase the volume, but also the accuracy and competitive value of their bids: estimodeling.

What is estimodeling?

Estimodeling, or model-based estimating, places the model at the heart of your estimating process. It involves quickly creating a 3D steel model to produce material takeoffs and generate other cost data for your project estimates.

Research has shown that merely being able to visualize your project in 3D significantly increases the accuracy and efficiency of construction estimates. But today’s estimodeling solutions in structural steel can offer much more than that.

In addition to being reliably faster and more accurate than traditional estimating methods, estimodeling also provides more data to help you build a better bid, eliminates manual data entry, and can integrate seamlessly with your MIS or MRP system for advanced fabrication management.

The estimodeling workflow

1. Build your model

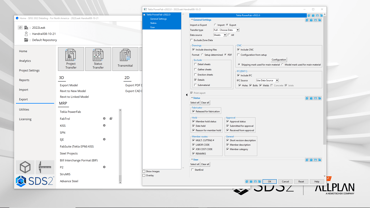

The estimodeling process starts, as you might guess, with modeling. In SDS2 and most 3D steel detailing software programs, you typically start by importing an IFC model, if provided, or by using a PDF overlay of the design drawings to quickly trace in your members.

What’s unique to SDS2 is the ability to automatically design connections based on your shop standards without the need for additional commands, extensions, or third-party systems. The connections aren’t just there for show. They come with expanded design calculations and complete node analysis to ensure that your estimate is based on a fully buildable and constructible design.

2. Refine your design for a competitive advantage

If efficiency and error reduction are your top concerns, you could stop at simply creating your model and using the data it provides to complete your estimates and material takeoffs. You’ll still see major improvements to your performance.

But if you’re looking to truly boost your competitive edge and create estimates that are accurate to the reality and capabilities of your shop, there’s a lot more you can do with the model without taking much more time.

The same automated features you use to create and view the model can also be applied to refine it, identify high labor operations and RFI situations, price-check design alternatives, and more. The more accurate your model, the more accurate your estimate can be.

Here’s a look at a few of the top tools within SDS2 that can power an effective estimodeling strategy:

Cost Estimator Tool

Select materials in the model to get a rapid material list and cost estimate for materials and operations, including holes, bolts, and welds. Combined with other features, this will allow you to quickly compare costs for alternative structural designs and connection design configurations. The output can be viewed in SDS2 or exported to an Excel report. Get the Cost Estimator tool here →

Status Display

Visually identify high cost and high labor operations in the model, such as beam web doublers, non-square cut ends, or failed connections.

Auto Standard Connections

As mentioned earlier, SDS2 automatically designs fully validated connections to your model based on fabrication preferences. To compare cost alternatives, you can quickly update your entire model by adjusting connection specifications for particular framing conditions. Pair this with the cost estimator tool to quickly compare design alternatives for a more competitive bid.

3. Leverage your data

Once your model is complete and refined to satisfaction, the rich data it provides is at your disposal. For some fabricators, the material list is enough—from that alone you can quickly complete your material takeoff with no more redundant data entry.

But you can get even more value from the estimating model when it’s integrated with your MRP or MIS software, where you can manage your material pricing, apply labor codes, visualize assemblies, and more, depending on your shop’s software platform.

SDS2 integrates with all major fabrication management software programs, including Tekla PowerFab, STRUMIS, and EJE.

And the integrations are getting more powerful all the time with more data compatibility, better communication between software platforms, and added tools for a smoother user experience.

The more data have at your fingertips, the more accurate your estimate is going to be—and that leads to stronger bids and better business outcomes.

|

4. Get a head start on your projects

The benefits of an estimodeling workflow don’t end when the bid is delivered. Assuming you win the project, the detailing model, material lists, and other data can now be used to give your project a head start.

Back when you were refining your model in SDS2, you were able to identify high labor operations and alternative structural designs. Once you win the bid, you can use that information to immediately send out RFIs, negotiate for lower cost designs, and more.

In addition, because you can run ABMs from the detailing model you created, you can get an early start on material ordering—a major advantage, considering today’s uncertain lead times and supply chain issues.

---

Despite the challenges of today’s markets, estimodeling is helping fabricators around the world fuel growth. The same 3D tools they use for detailing can help them overcome the limitations of their manual estimating workflows and achieve high bid volume with greater accuracy—and that’s just the beginning.